You’d also explain the problem to production managers and tell them how the repairs are progressing. You’d fix the problem there and then or, if necessary, arrange for the equipment to be replaced. In emergency maintenance you would respond immediately when equipment breaks down. Inspect the quality of maintenance work.Fit new parts as required or as part of a regular replacement rota.Check and calibrate instruments to make sure they are accurate.Organise schedules for routine servicing.If you work in preventative (planned) maintenance you would: Lifts, escalators, walkways and airport skytrains Check and replace worn belts and hoses repair cooling system and heater problems check and measure brake lining thickness clean and adjust brakes check.Equipment and facilities for generating power including hydro-electric, wind turbines, solar and marine energy technology, fossil fuel and nuclear power stations.Machines and equipment used on railways and roads.Laboratory equipment in hospitals or used to manufacture drugs and medicines.Machinery used on production lines in factories.You’d need to understand engineering drawings and be aware of health and safety legislation.

#Maintenance technician manuals#

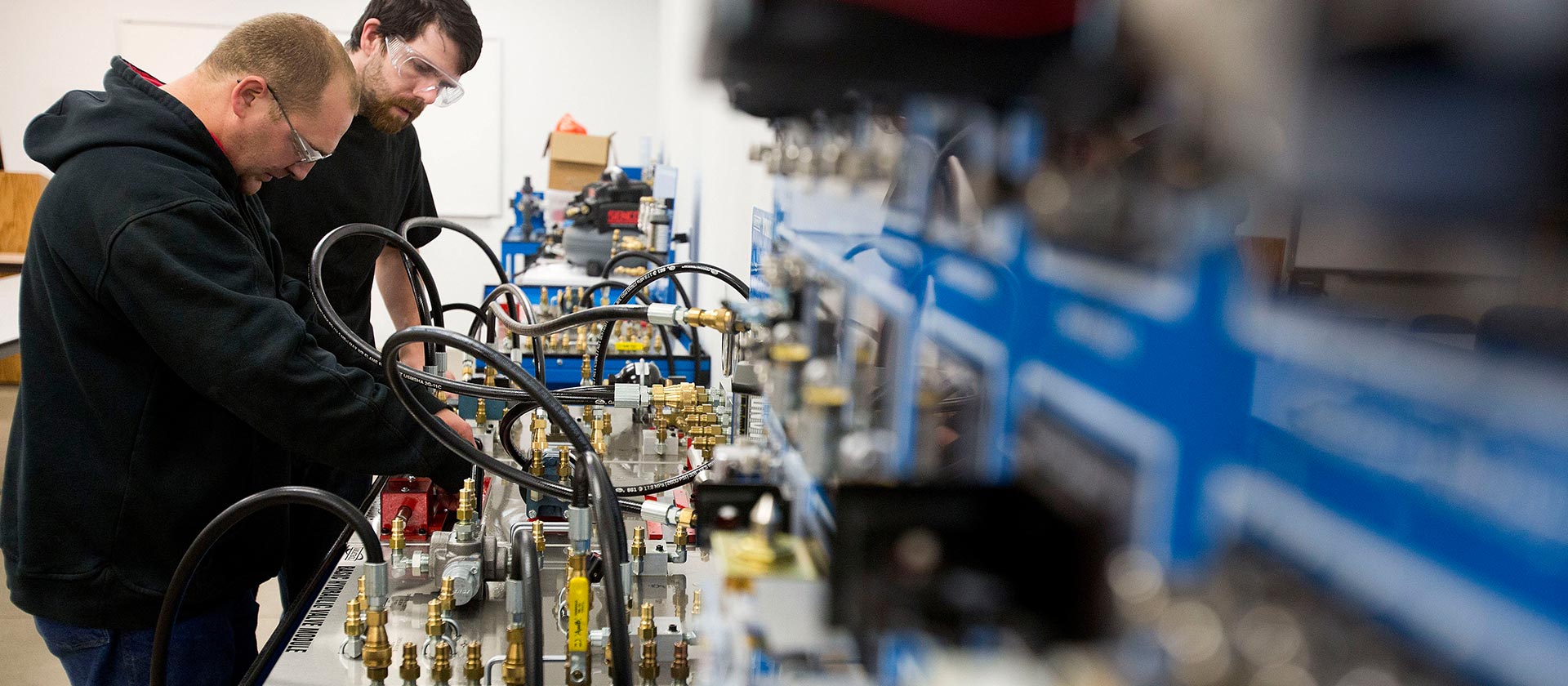

You would follow manufacturer's technical manuals and use testing instruments and tools to help locate faults. You would look after and fix electrical and mechanical equipment used in industry, from factories and power stations to aircraft and escalators. The Technician is responsible for a variety of tasks which ensure the efficiency and reliability of all Company tooling or production equipment and.

0 kommentar(er)

0 kommentar(er)